Bonding double-sided adhesive tapes

After we have presented our recommendation for cleaning and pre-treatment of surfaces with isopropanol in an earlier article, we would now like to give you our recommendations for the processing of double-sided adhesive tapes in this article. Particularly with high-performance adhesive tapes such as the 3M™ VHB GPH or a Coroplast SPT, conscientious processing is crucial for the adhesive tape to develop its full performance.

1. Application of the adhesive tape

– Ideally, the processing temperature (object and ambient temperature) should be between 15 °C and 25 °C. If this temperature window is greatly below or exceeded, it is advisable to adjust the temperature accordingly or to postpone the time of bonding in order to achieve an ideal result.

– Place the tape on the surface to be bonded, pull tight but do not overstretch. Avoid air pockets. If necessary, remove air pockets with gentle pressure.

– Do not stick the initial piece of tape that has been touched. This can be left over and cut off in the aftermath.

– For glass surfaces, the use of a special primer (for example the: 3M™ Silan Glass Primer) is recommended.

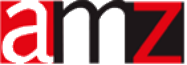

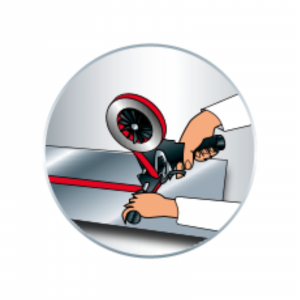

2. Press on

– Press down the adhesive tape well with approx. 2 kg/cm2. Here, the 3M™ Hand Roller 2745 provide good assistance, as the weight of the roller ensures the correct contact pressure without additional effort.

3. Remove protective cover

– Remove the protective cover in one piece to avoid stop marks and associated irregularities in the bond.

– Important: Do not touch the adhesive surface!

4. Joining

– After removing the protective cover, perform the bonding of the second joining part promptly to avoid contamination on the open bonding surface.

– Avoid air pockets and apply the second part to be joined in one go, if possible.

– Pressure with approx. 2 kg/cm2.

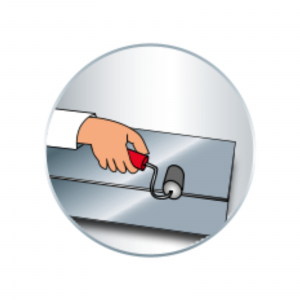

5. Wait for final adhesive strength

– Do not load until the dwell time has elapsed. 50% of the final adhesive strength is reached after approx. 20 minutes.

– After 24 hours, approx. 90% of the adhesive strength is achieved.

– Final tack at 20 °C is expected to be reached after 72 hours.

– Heat can accelerate the process.

AMZ – Your professional consultant for adhesive tapes and surface joining technology

These instructions are valid for most common double-sided adhesive tapes in the industrial and in the semi-professional field. Of course, it is always advisable to check the corresponding data sheet of the adhesive tape for any special features and processing instructions. We will be happy to answer any questions you may have or to provide you with individual advice. Simply email us at info@amz-group.de or reach us by phone at 06106-779600. We look forward to hearing from you!

Disclaimer

All information, technical data and recommendations in this document are based on tests or empirical values that AMZ considers reliable. These are average values and are not intended to be a basis for specification. Also, the use and performance characteristics of a product purchased from AMZ in a particular application may be affected by numerous factors beyond AMZ’s control, such as the conditions of use and the time and circumstances under which the product’s performance is called upon. Since only the user knows these factors and can control them, the user must always check and decide for himself whether the product purchased from AMZ is suitable for a particular purpose and for his process or application. All matters relating to liability for this product are governed by the respective purchase contract provisions, unless otherwise provided by law.